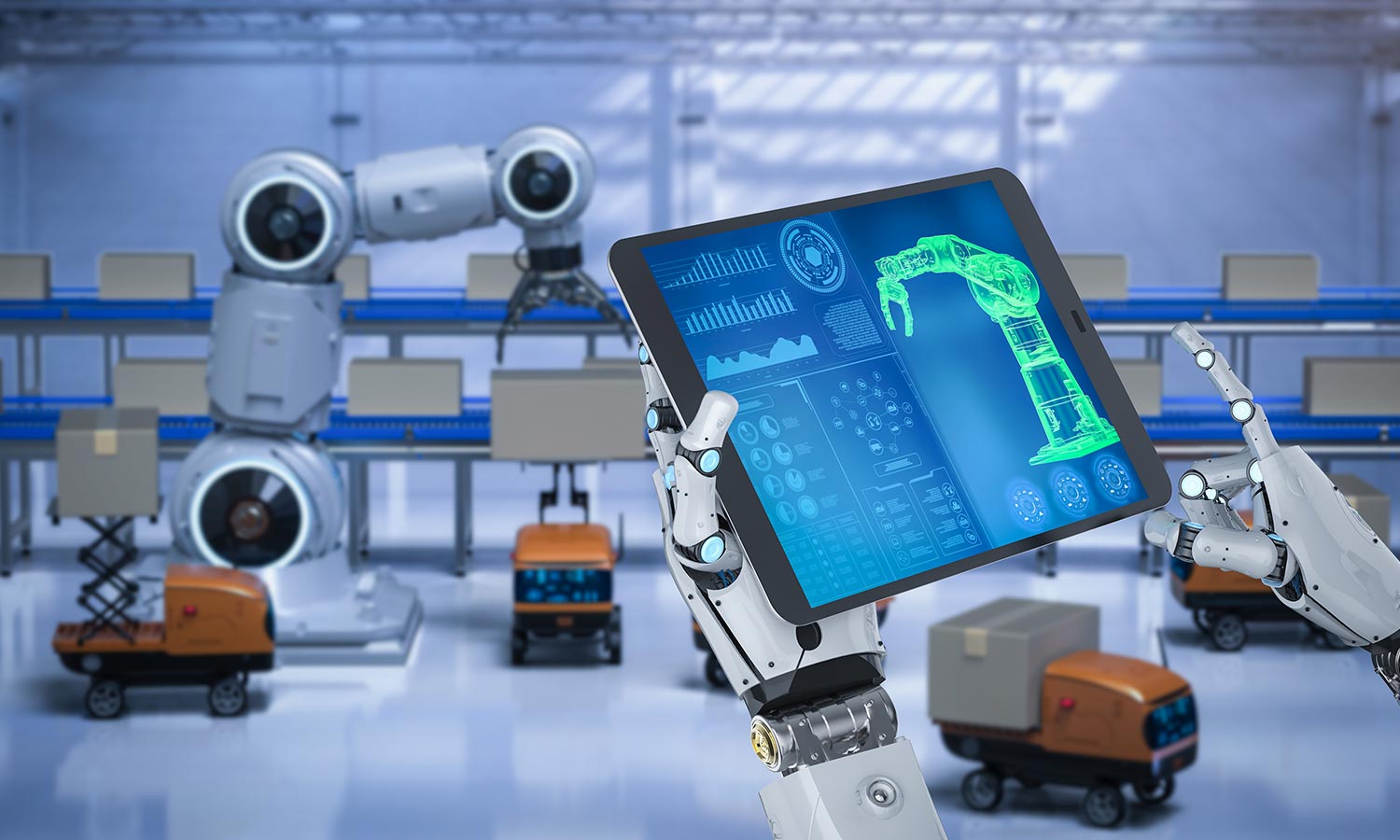

Ai-driven Predictive Maintenance: Why Hannover Is The Smart Choice For Manufacturing Investments

As industries across the world transition toward Industry 4.0, Hannover has emerged as a global hub for smart manufacturing and industrial innovation. With a strong focus on AI-driven predictive maintenance, the city is attracting top-tier investors looking to optimize production efficiency, reduce downtime, and drive sustainability.

Why is Hannover leading the way?

Hannover offers a high-tech industrial ecosystem, government support, and a thriving research and development (R&D) landscape, making it an ideal destination for companies seeking to integrate AI-powered predictive maintenance into their operations.

This blog explores how Hannover is at the forefront of AI-driven predictive maintenance and why investors should seize the opportunity to establish manufacturing ventures in the city.

Why Hannover is a Leader in AI-Powered Predictive Maintenance

Hannover’s manufacturing and industrial automation ecosystem is built on a foundation of technological advancements, research excellence, and strong public-private partnerships. Key factors that make Hannover an investment hotspot include:

- Hannover Messe – The world's largest industrial technology trade fair, where cutting-edge AI solutions for predictive maintenance are showcased.

- Strong AI & Industry 4.0 Research – Universities and institutions like Leibniz University Hannover are pioneering AI-powered manufacturing solutions.

- Smart Factory Infrastructure – Hannover has developed testbeds and pilot projects for industrial AI, allowing companies to validate and deploy AI-driven predictive maintenance solutions.

- Government Incentives for Industrial AI – Germany provides financial grants and tax benefits for businesses investing in AI, automation, and sustainability.

The Role of AI-Driven Predictive Maintenance in Hannover’s Industrial Growth

AI-driven predictive maintenance is transforming Hannover’s manufacturing landscape, enabling companies to:

- Minimize Downtime – AI systems predict machine failures before they happen, reducing costly unplanned shutdowns.

- Enhance Productivity – Factories achieve higher output with optimized equipment performance.

- Reduce Maintenance Costs – AI-driven insights eliminate unnecessary maintenance expenses.

- Improve Sustainability – Energy-efficient AI systems help reduce waste and carbon emissions.

- Attract Top Talent & Innovation – A smart factory environment fosters a culture of R&D, attracting skilled professionals and investors.

How AI-Powered Predictive Maintenance Works in Hannover’s Factories

Hannover’s industrial sector is rapidly adopting AI-powered predictive maintenance using:

- IoT-Enabled Smart Sensors – Real-time tracking of machine health, vibration, temperature, and performance.

- Machine Learning Algorithms – AI analyses historical and real-time data to detect anomalies.

- Cloud-Based AI Platforms – Data is stored, processed, and used to predict potential failures before they occur.

- Automated Alerts & Scheduling – AI-powered dashboards notify engineers of upcoming maintenance needs, optimizing repair schedules and resources.

Key Industries in Hannover Benefiting from AI-Driven Predictive Maintenance

- Automotive & EV Manufacturing – Companies like Volkswagen and Continental in Hannover are using AI to optimize assembly lines and reduce production errors.

- Aerospace & Defence – AI-powered maintenance is enhancing safety and reliability in aircraft manufacturing and component testing.

- Pharmaceuticals – Hannover-based pharma companies are adopting predictive AI solutions to ensure regulatory compliance and quality assurance.

- Food & Beverage – Smart factories in Hannover are preventing equipment failures, reducing downtime, and ensuring food safety standards.

- Electronics & Semiconductor Production – AI solutions monitor precision manufacturing processes to prevent defects and optimize efficiency.

Why Investors Should Choose Hannover for AI-Powered Manufacturing

Hannover is not just embracing AI-driven predictive maintenance—it is leading the charge. Here’s why investing in Hannover’s manufacturing sector is a smart decision:

- Europe’s Smart Factory Hub – Hannover is home to some of the most advanced AI-driven industrial facilities.

- Government Support & Incentives – Germany offers funding for AI integration, tax incentives, and support for green industrial transformation.

- Strong R&D and Talent Pipeline – Hannover’s universities and research centers produce top AI engineers and data scientists for industrial applications.

- Strategic Location & Connectivity – Hannover’s world-class infrastructure ensures seamless supply chain integration across Europe.

- Hosting of Hannover Messe – The city provides an unparalleled global platform for networking, innovation, and business expansion in the AI and manufacturing space.

Conclusion

Hannover is at the heart of the AI-driven manufacturing revolution, setting new standards for predictive maintenance, smart factory automation, and industrial innovation. For investors looking to capitalize on Industry 4.0, Hannover presents an unmatched opportunity—a thriving ecosystem, advanced AI research, and a government committed to technological progress. With AI-powered predictive maintenance already transforming industries, the future belongs to businesses that invest in Hannover’s cutting-edge industrial landscape today.

Twitter

Twitter